Simply better in every way.

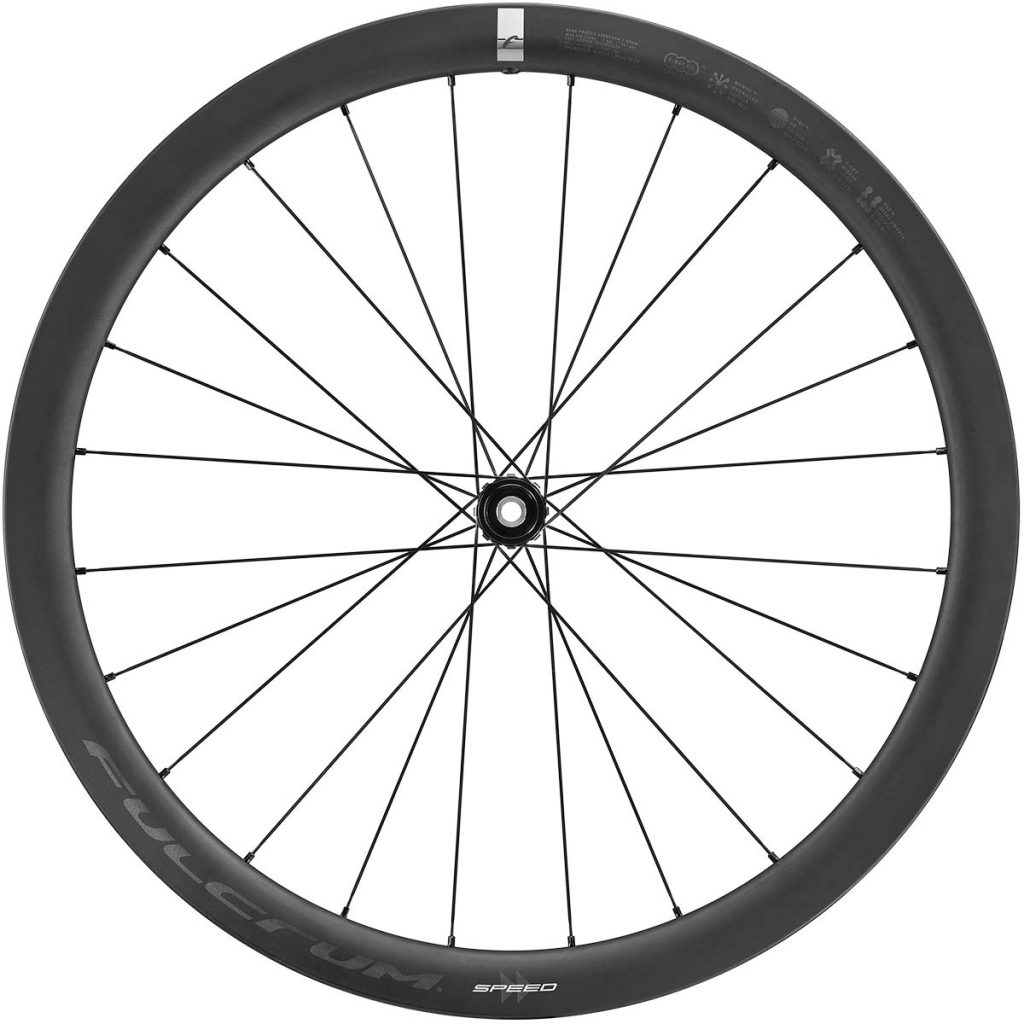

The new Fulcrum Speed 42 and 57 are Fulcrum’s step into a new era and dimension, the result of the fundamental synergy between form and function: Form, Function, Fulcrum.

Simply better

in every way

+2 mm higher

+4 mm wider

+6 ratchet teeth

Up to 85 grams lighter

Up to 17% better handling

Up to 10% better reactivity

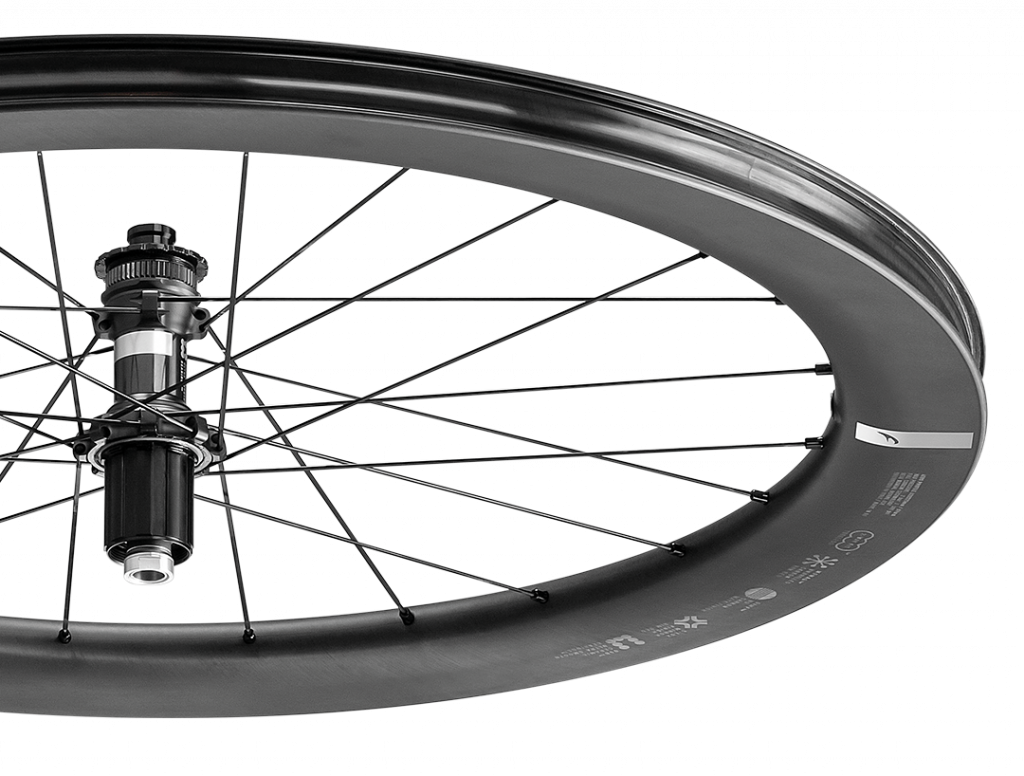

The spokes

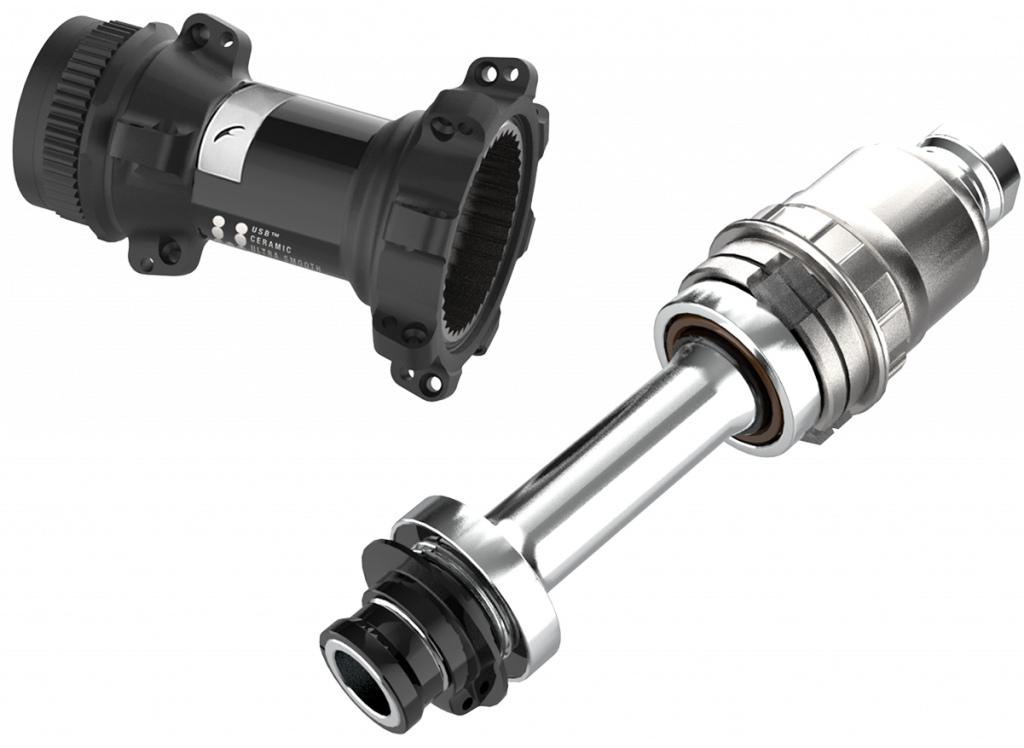

The hubs

The bearings used in the Speed 42 and 57 are cup and cone and use the USB™ system (Ceramic Ultra Smooth Bearings) that provides unparalleled levels of smoothness.

The hub system uses an aircraft grade aluminium axle, which allows it to work with centesimal tolerances guaranteeing performance and durability.

Fulcrum wheels are designed for a specific use and function and therefore do not include additional adapters or spacers to be used with the axle, as can often be found in other products. This ensures an extremely solid system that always works with perfect alignment.

The ratchet system of the freewheel has been reinforced and increased in size so that now it houses 36 teeth. The wheel is available with Campagnolo N3W, Shimano HG and Sram XDR freewheel bodies.

The level of detail required to describe and list all the technologies and benefits of the new Speed 42 and Speed 57 wouldn’t fit in one press release.

What we wanted to do is convey the perfect ride feel that these wheels offer. Lightness, handling, aerodynamics and responsiveness have never been so well balanced, the result of the perfect synergy between form and function.

Tech specs

Speed 42

Tyre Type: 2-Way Fit™ tubeless

Rim Height: 42 mm

Rim width: inner 23 mm

Spokes: Aero, Straight-pull

Bearings: USB™ Ceramic

Weight: 1,410 g

Speed 57

Tyre type: 2-Way Fit™ tubeless

Rim height: 57 mm

Rim width: inner 23 mm

Spokes: Aero, Straight-pull

Bearings: USB™ Ceramic

Weight: 1,495 g

Combo 42/57

Tyre type: 2-Way Fit™ tubeless

Rim height: 42/57 mm

Rim width: inner 23 mm

Spokes: Aero, Straight-pull

Bearings: USB™ Ceramic

Weight: 1,460 g

The start of a new era